Behind the scenes with PC modder Derek Wilson, builder of our epic new OMNI PC

It’s not easy to stand out in the competitive field of custom PC building and modding, but that’s exactly what Derek Wilson, known online as RhoadsPC, is doing. As a bespoke computer builder, he specializes in making absolutely unique systems for a variety of high-profile clients, creators, and gamers. His projects start with cutting-edge PC components, and they end with one-of-a-kind computers that offer an unbeatable blend of craftsmanship, style, and performance.

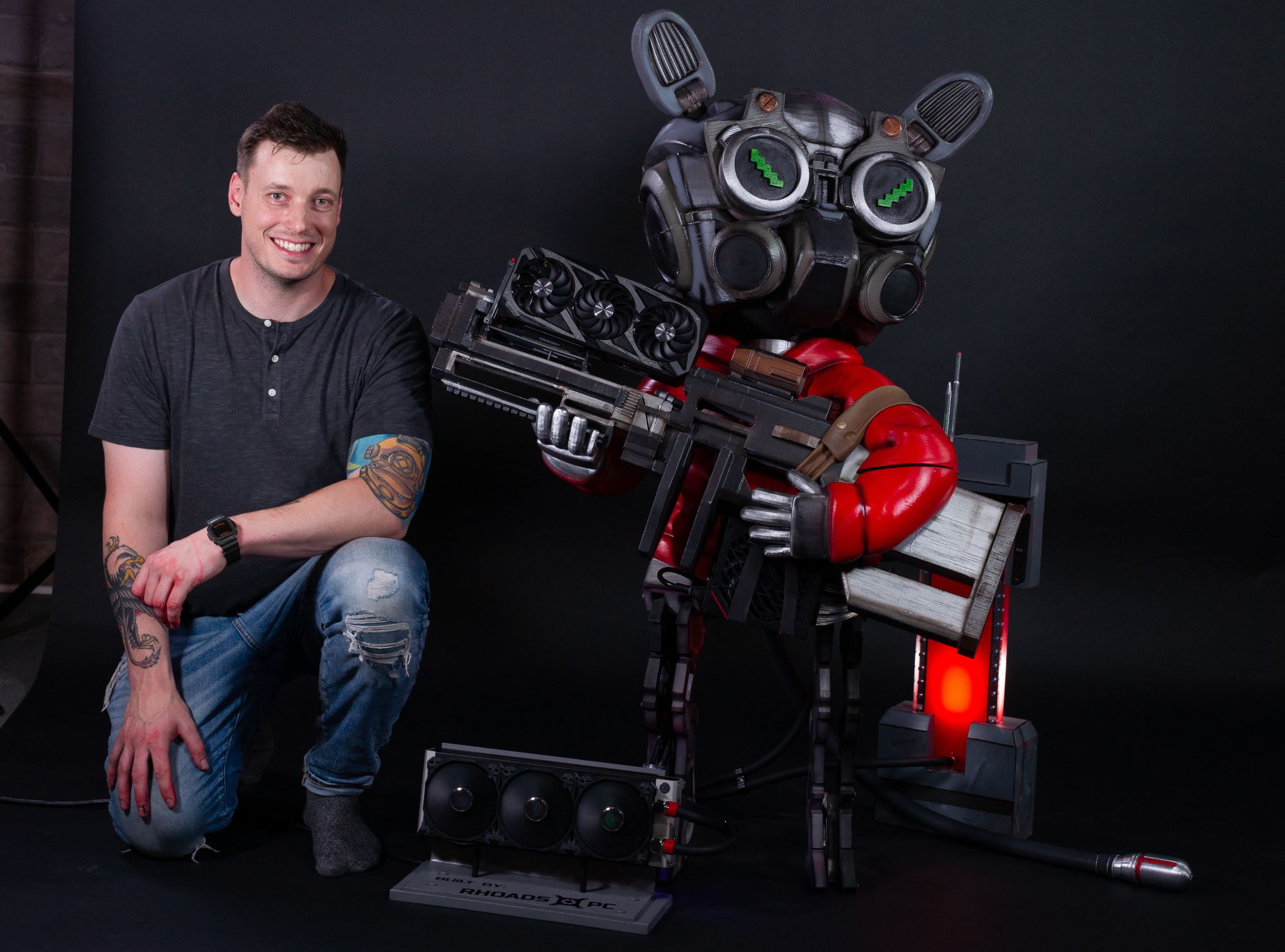

Derek gets to add ASUS to his ever-growing list of satisfied customers, because we commissioned him to build a PC for us based on the ROG Saga character OMNI—and the finished project is spectacular. If at all possible, join us at PAX West 2022 or at future ROG events to see this build in person. This four-and-a-half foot tall, fully functional PC cleverly houses a complete high-end gaming PC in the form of a robotic sci-fi mouse.

Derek had to overcome a laundry list of engineering challenges to bring the OMNI PC build to life. With the precision and power of an i2R CNC machine, a healthy dose of creative ingenuity, and no small amount of old-fashioned grit and determination, Derek was able to produce a stunning PC build. But where did Derek develop the skills to make such a unique PC? How did he get his start in this field? What did he learn as he constructed the OMNI PC? We sat down with Derek to learn more about his story and his process.

Finding the right creative outlet

Even from a young age, Derek showed a restless creative energy that compelled him to start new projects and learn new skills. He grew up in a rougher neighborhood in northeast Calgary. He credits his humble beginnings with shaping his mindset. In his words, “I think my group of friends made me be a more creative person because we always had to find external things to do and ways to have fun within a limited amount of resources.”

With the support of his mother, Derek started to channel his creative energy into music. A friend invited him to join a band, and Derek agreed to play bass without having much idea what that would entail—or even an instrument to play. He said, “We only had so much money for this kind of thing, so my dad had actually given my mom money to pay for braces, and my mom instead bought a bass guitar and an amp to go with it.”

Unfortunately for Derek—but perhaps fortunately for us—the band never took off, and the bass ended up gathering dust. But he never stopped looking for new ways to create, and that’s when he discovered PC building and modding. “When I took a break from music in my twenties, I was missing that creative outlet,” he explained. “I picked that back up in 2018 when I built a computer for myself and learned about PC modding. I didn’t even know it was a thing.”

Growing pains

One build in particular led Derek into modding—but it wasn’t his most successful project. “This was for a friend who went out on a limb. He was the first person who said, I’ll pay you to do a build.” Derek put it all together, wrote his tag RhoadsPC on it with a Sharpie, and sent it off. Unfortunately, his friend sent it right back, saying that it didn’t work.

The problem was easy to diagnose—a key cable for the CPU was unplugged. But Derek felt bad for his friend, and wanted to make up for his mistake by going above and beyond. “I thought I would do something special for him, so I decided that I was going to paint it,” he said. He learned to take the computer apart by drilling out the rivets, painted it, and even made custom vinyl stencils for it with his Cricut.

His friend was so pleased with the customized (and now fully functional) PC that Derek started offering modding services for the other builds that he was commissioned to make. That’s when his career as a PC builder modder started to take off. People love having an absolutely unique computer, and Derek was rapidly learning the skills he needed to provide that for them.

Teaming up with ASUS

Like many PC enthusiasts, Derek can’t resist an opportunity to get his hands on cutting-edge hardware. One of his main motivations for offering his building services to friends and family was getting the chance to check out different components and how they performed. “ROG parts were a big part of that,” he said. “I was always really excited to see the high-end ROG motherboards that overclockers were using to really max out their processors—and the motherboards could handle it.”

Derek came across our radar when he won a PC from us in a contest. We’d been on the lookout for a PC modder who could operate a CNC machine, and Derek checked both of those boxes. That’s when we asked if he was interested in building a PC like none other: a full-size replica of the ROG Saga character OMNI that doubles as a fully operational gaming PC.

Derek couldn’t wait to get started. “I always try to push the boundaries,” he explained. “I love it when a client comes to me with their ideas for a PC mod or a themed build, and they ask me, ‘Can this be done?’ and they trust me to bring it to life. That’s my favorite part of this. So when ASUS approached me, I knew I had to put my whole heart and soul into it to make this project come to life.”

The scale of the project was a little intimidating, though. When Derek looks back on what it felt like to put together the preliminary prints and start thinking through everything he’d need to do to make a four-and-a-half foot tall PC build, he admits that it felt quite scary. But his experiences in life had taught him to trust himself. He explained, “It was kind of like my day job where there are aspects like wind and weather that throw you off, but I know because of my confidence in myself that I’ll be okay at the end of the day and get the job done.”

Building OMNI piece by piece with an i2R CNC machine

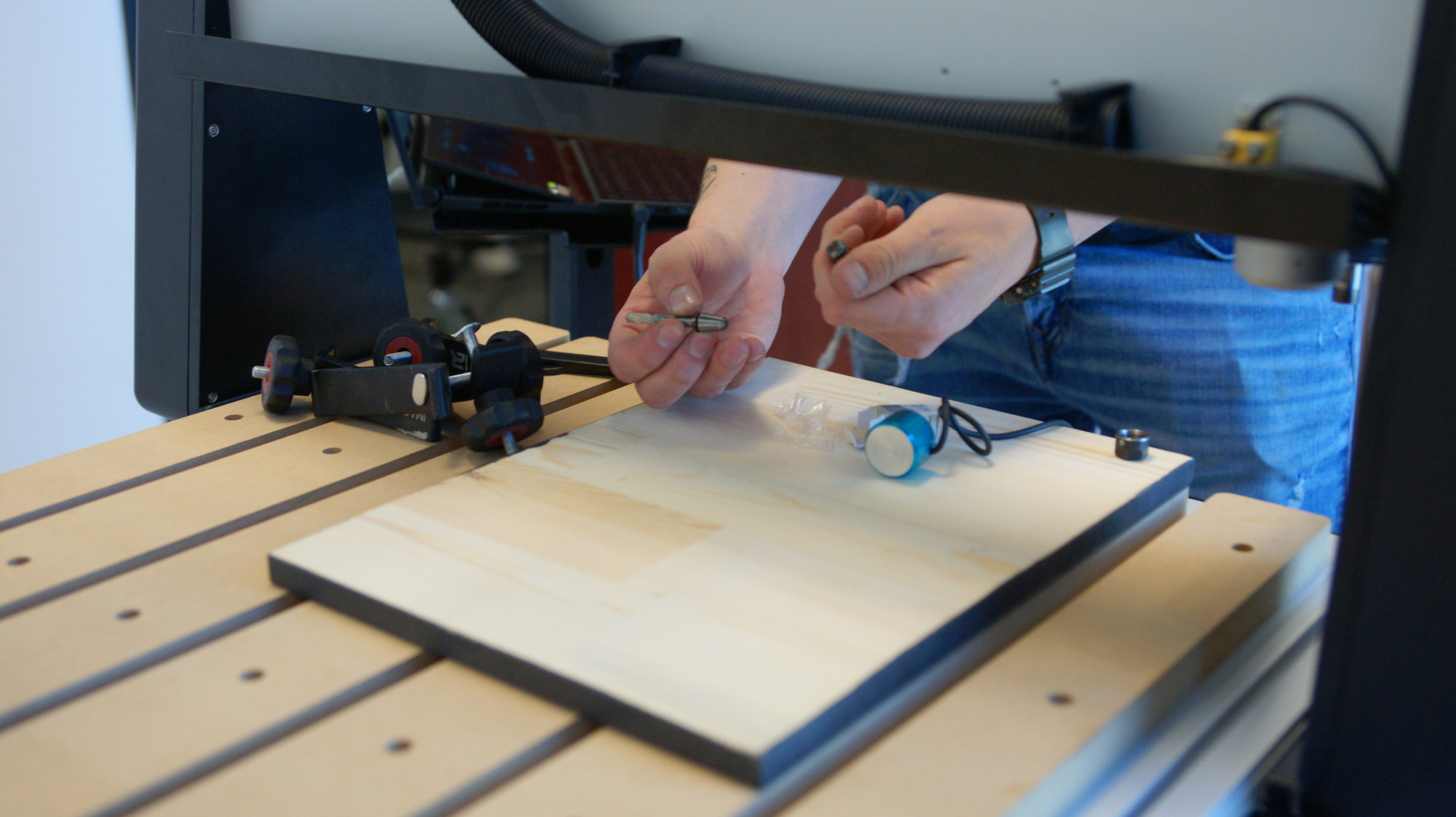

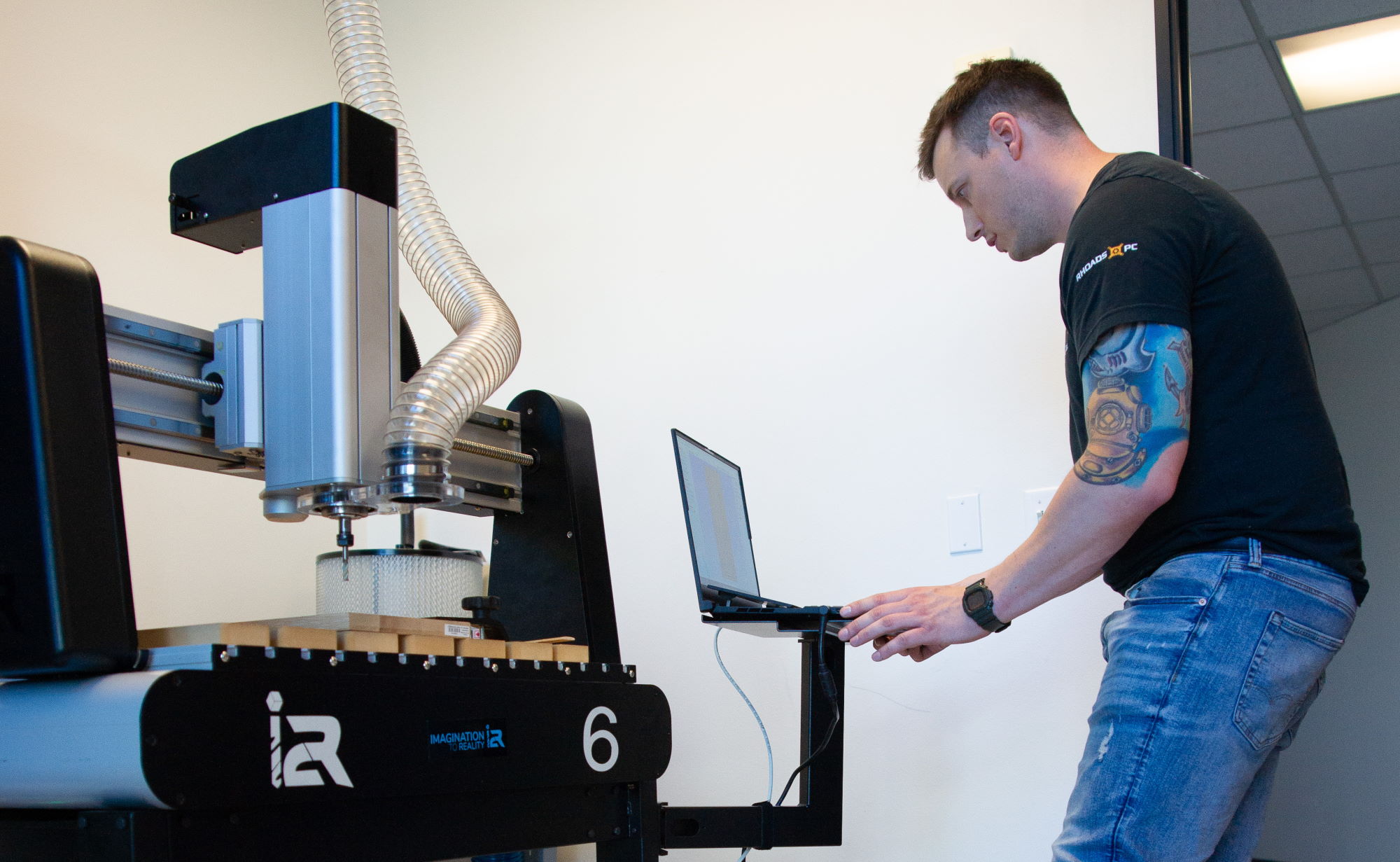

Just about anybody can assemble a PC if they can take the time to learn about the components and the process, and a wide range of people can learn how to do basic mods for their PC. But to bring his ideas to life, Derek needed advanced professional tools. The i2R CNC machine that he uses in his personal shop—and that we have set up in our own PC DIY workshop—was just what he needed. Derek said, “When you really want to step out of the box, working with a company like i2R and incorporating a CNC machine into your shop and to what you do can totally bring your builds to the next level.”

The i2R machine helped Derek take his creative vision and make it a reality. “As I got going on the project, I could tell this is going to be huge. You have to remember that I’m building a four foot tall giant mouse robot,” he explained. “So I switched the parts from pine to oak because it’s a harder, stronger wood. I also used cast acrylic, three different thicknesses. The biggest piece was an inch thick, which the i2R handled no problem.”

The i2R proved invaluable for constructing the reservoir for the OMNI build’s liquid-cooling loop. “It’s a good example of what you can do with the i2R when you really want to customize the cooling, or custom distro plates, reservoirs, pump block, things like that,” Derek said. “The i2R machine fit the bill for the learning curve, the support, and what the machine can do for what I need.”

Unexpected challenges

Of all the pieces for the OMNI build, the most challenging for Derek to construct was the head. While he could make the body and the gun as solid pieces, the head had to be hollow or else it would have been too heavy. All told, Derek printed the head in about 17 different pieces and then glued them together. “It was like playing Lego,” Derek laughed. Bondo, primer, and a lot of sanding brought the pieces together into one cohesive whole.

If OMNI were destined to stay in one place in our PC DIY room, Derek’s job would have been a lot easier. But OMNI was born to travel, and that required Derek to do some experimenting. “Designing and building this project was one thing. But designing it so that it could be taken apart and transported and put back together easily, to be put on display and used at different gaming events, brought on a whole other set of challenges,” Derek explained. He ended up using a variety of strategies to make the build easy to take apart, transport, and reassemble. “For example, the legs I made so you can take them off by four pins, the hand goes on with a piece of Velcro, and the head can come off with a wooden dowel.”

The support he needed

Derek understands that there are modders out there who are a little hesitant to get started with using a CNC machine. “A barrier to this stuff is the learning curve of how do I get it going, how do I get it started, what do I need to actually make something,” he told us. “With my i2R machine, I purchased it in December, it was delivered in January, and on the day I set it up I was making something.”

For Derek, one key factor in his success with the CNC machine was the staff at i2R. “The guys at i2R are great,” he said. “They’re there for the whole process, and they’re available for the setup, the walkthrough of the machine. They get you making stuff as soon as possible. Every day I’ve turned on my CNC since I’ve been able to make something, and any time I’ve had a question or I’ve had an issue, it’s as easy as I can call them, and they’ll answer my question over the phone.”

The OMNI build required Derek to use a variety of materials, and the i2R machine gave him what he needed. “Some of my favorite things about the i2R machine specifically would be the hold-down system. It comes with a set of clamps that are excellent. I haven’t had a problem holding down any materials I’ve gone to cut. It has a very powerful spindle, so I’ve been able to cut through aluminum, acrylic, and different types of wood including oak and pine, and it’s given me no issues.”

Not just for gaming

To operate a CNC machine, you need a laptop. Throughout the build, Derek found that the specialized hardware of the ROG Zephyrus Duo 16 gaming laptop streamlined his workflow. His process actually involves two apps: VCarve, which he uses to design his cuts and tool paths, and UCCNC, which communicates directly with the machine.

On an ordinary laptop, Derek would have to flip back and forth between the two apps, but the Duo 16 is no ordinary laptop. Its integrated second screen makes sure you’re always ready to multitask—even when it’s mounted on the laptop of a CNC machine. As Derek told us, “I could have both programs open, which allowed me to make sure that everything went smoothly throughout my project.”

Built for gaming glory

The OMNI build’s epic exterior cried out for an equally epic selection of components. To give this PC unquestioned gaming prowess, we built it on the power of Intel’s latest 12th Gen platform. The ROG Strix Z690-I Gaming WiFi gave us supreme gaming power in a striking compact profile. We installed an Intel Core i9-12900K CPU into this board for epic performance, and paired it with a 32GB kit of Kingston’s high-end FURY Beast DDR5 RAM. A cooling solution from EK Water Blocks keeps this potent processor cool—in addition, of course, to the custom pieces that Derek made specifically for the build.

Graphics horsepower comes from none other than an ROG Strix GeForce RTX 3080 graphics card—and we use a riser cable to mount this glorious card as part of OMNI’s gun. Kingston kicked in a pair of its 1TB KF Renegade SSDs to support a spacious, high-speed gaming library, and GS Customz supplied the cables that connect it all together. Our own ROG Strix 850W PSU delivers stable power to all these high-end components. All together, these components deliver performance worthy of the larger-than-life enclosure that Derek constructed for this build.

No ordinary build

With OMNI constructed and the PC components all installed, Derek could finally enjoy the fruits of his labor. “That moment of seeing OMNI with the parts actually installed was when I was finally like, 'yes, I love this project,' because before that it was quite scary,” he admitted. “On a scale of 1 to 10 for difficulty out of what I’ve done, this was easily a 9 out of 10. There were all kinds of challenges.”

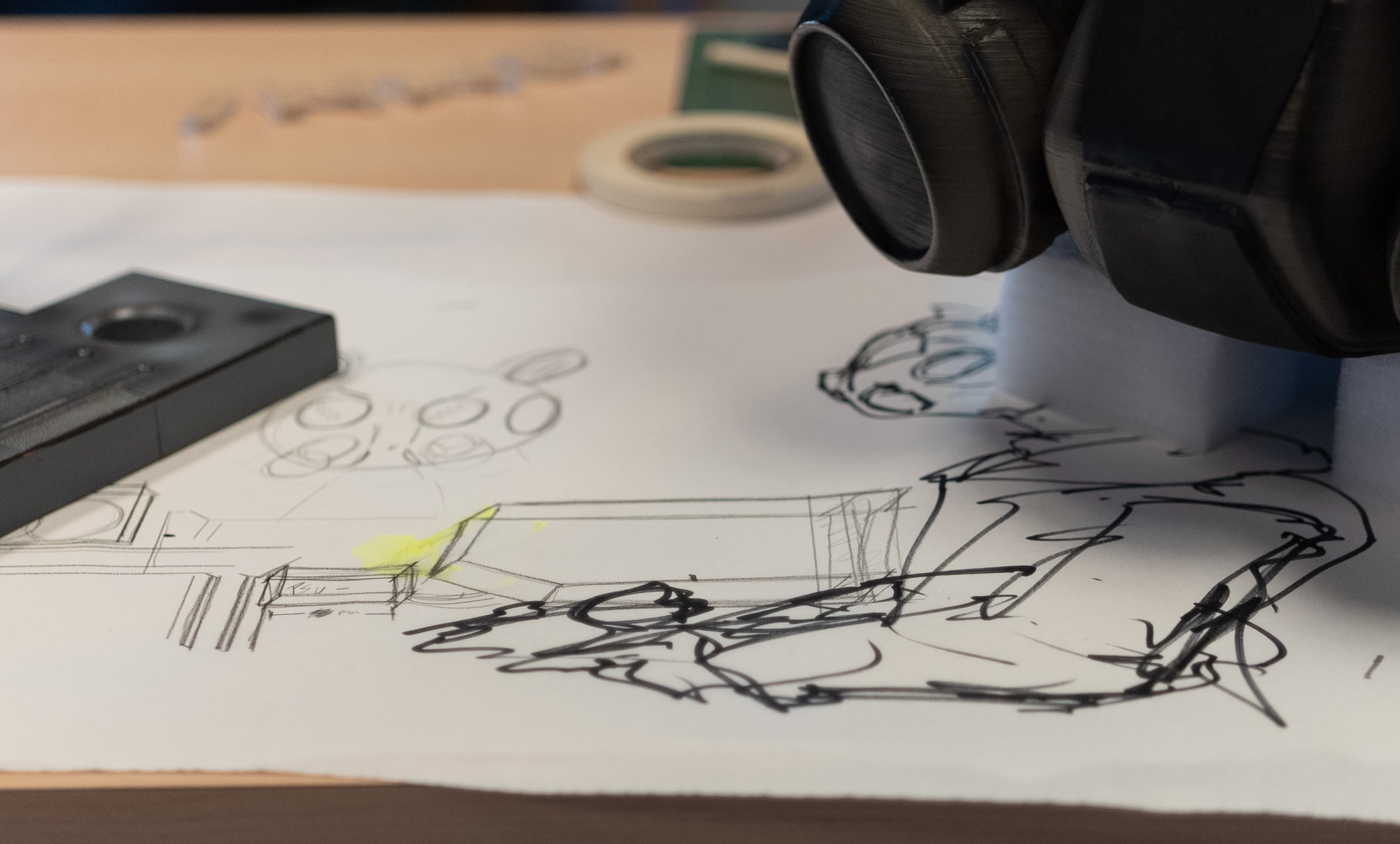

In the end, Derek thinks that it was those very challenges that made the process of building OMNI so special for him. “Every PC that I build holds something special. But when I look back on this journey, I want to remember the struggles, the late nights of sketching, the problem solving. I want to remember the journey of getting here at ASUS, even the struggle of the airline losing some of my supplies. I want to remember all the people that I met along the way because this experience is so much more than just the outcome.”

Check out OMNI in person at PAX West

We couldn’t be more pleased with Derek’s work on the custom OMNI PC. To learn even more about his story and catch some behind-the-scenes insights about his design process, check out our three-part video series. We’re also thrilled to showcase his work at our booth at the PAX West event. Derek’s love for creating unique PC mods is unmistakable when you see it in person, so join us between September 2nd and 5th in Seattle, Washington to check out the OMNI build for yourself. You’ll also get the chance to check out our latest hardware, interact with ARUUU from the ROG Stream Team, and participate in exclusive contests and giveaways.